MATEC Electronics partners with one of the world’s well -known technology driver PCB manufacturer company Amphenol in order to support entire life-cycle of the projects from variety of Markets such as military-defence, aerospace and industrial fields. MATEC’s role begins from first design activity with design engineers, following "design for manufacturability” concept and prototyping to series production. New applications are often developed in partnership with customers to deliver optimum performance under extreme conditions. Unrivalled technical capabilities coupled with innovation and close customer/supplier relationship ensure a comprehensive service-backed offering.

MATEC’s engineering service team acts as advisory and checks all of the models from pre-design stage for manufacturability and production stage to supply most efficient solution in terms of cost and technology. After the design data has been fixed our standart lead times start from 10-15 days. We also support our customers catch their project deadlines with faster lead times in critical situation.

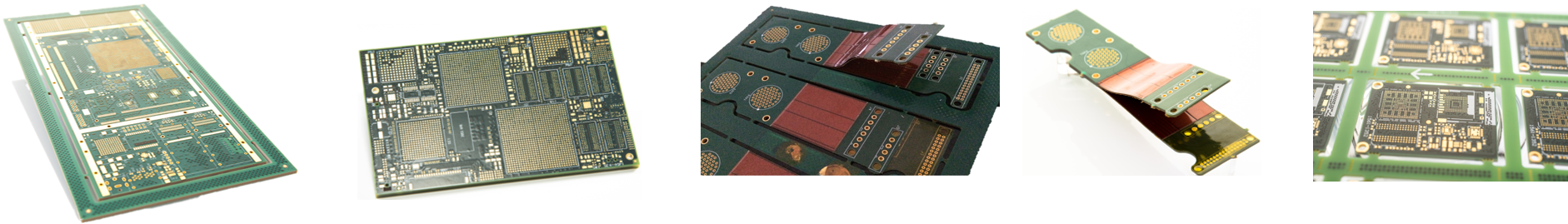

Our aim is to always focus on technology and focusing on solving most challenging problems or requirements. Our standart PCB production capability starts from standart from sinle layer boards to 40+ layered boards, in addition to Flex , Flex – Rigid solutions and HDI ( High Density Interconnect ) solutions. Our product and technology capabilities can be found in the table below.

| Capability |

Standart 2013

Microns/Mils |

Advanced 2013

Microns/Mils |

Road Map

Microns/Mils |

|

| Inner Layer |

Track

GAP |

50 microns - 2 mils

50 microns - 2 mils |

38 microns -1.5 mils

38 microns - 1.5 mils |

25 microns - 0.8 mils

25 microns - 0.8 mils |

| Outer Layer |

Track

GAP |

75 microns - 3 mils

75 microns - 3 mils |

63 microns - 2.5 mils

63 microns - 2.5 mils |

50 microns - 2 mils

50 microns - 2 mils |

| Laser via pads |

Internal Pads |

0.250 mm -10 mils

300 microns - 12 mils |

200 microns - 8 mils

225 microns - 9 mils |

|

| Mechanical via pads |

External Pads

Internal Pads |

450 microns - 18 mils

500 microns - 20 mils |

350 microns - 14 mils

450 microns - 18 mils |

|

| Aspect radio | 10:1 | 11:1 | 12:1 | |

|

Solder resist

solder mask clearence |

40 microns - 1.6 mils |

30 microns - 1.2 mils | 20 microns - 0.8 mils | |

| Copper thickness |

Min

Max |

12 microns - 0.5 mils

210 microns - 9 mils |

9 microns - 0.4 mils

210 microns - 9 mils |

5 microns - 0.2 mils

>210 microns - 9 mils |

| Min Dielectric thickness | 25 microns - 1 mils | 25 microns - 1 mils | <25 microns - 1 mils | |

| HDI |

Min

Max |

1+N+1

5+N+5 |

1+N+1

6+N+6 |

1+N+1

>6+N+6 |

|

MAX panel size

Standard |

24"x21" / 609.6 mm x 533.4 mm

24"x18" / 609.6 mm x 457.2 mm |

24"x21" / 609.6 mm x 533.4 mm

24"x18" / 609.6 mm x 457.2 mm |

24"x21" / 609.6 mm x 533.4 mm

24"x18" / 609.6 mm x 457.2 mm |

|

| Panel Thickness |

Min

Max |

0.03" / 0.08 mm

0.20"/5.00 mm |

0.016" / 0.04 mm

0.21" / 5.3 mm |

0.001" / 0.25 mm

>0.21" / 5.3 mm |

| Max layer count | 40 | 50 | >50 | |

|

Mic mechanical hole

Buried pair mechanical

Min diameter laser via

Buried pair laser |

Min

Min

Min

Min

|

250 microns - 10 mils

150 microns - 6 mils

100 microns - 4 mils

70 microns - 2.8 mils |

200 microns - 8 mils

150 microns - 6 mils

75 microns - 3 mils

<70 microns - 2.8 mils |

200 microns - 8 mils

150 microns - 6 mils

75 microns - 3 mils

<70 microns - 2.8 mils |

| Mechanical depth control | +/- | +/- 25 microns - 1 mils | +/- 15 microns - 0.6 mils | +/- 10 microns - 0.4 mils |

| Control Impedance | % | +/- %10 | +/- %7 | > +/- %7 |